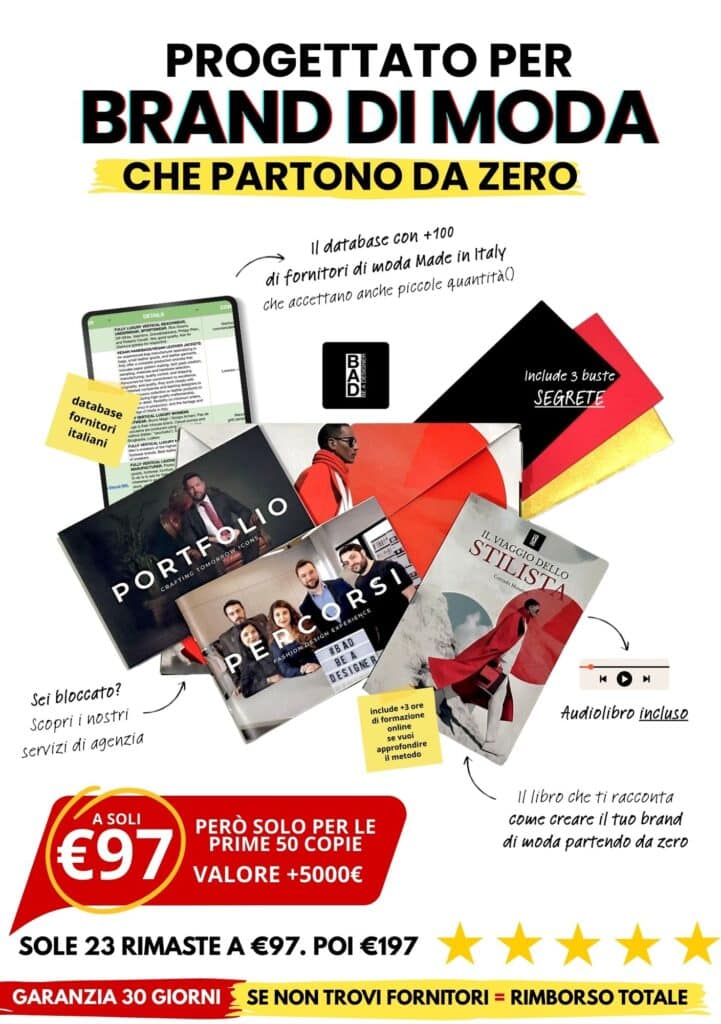

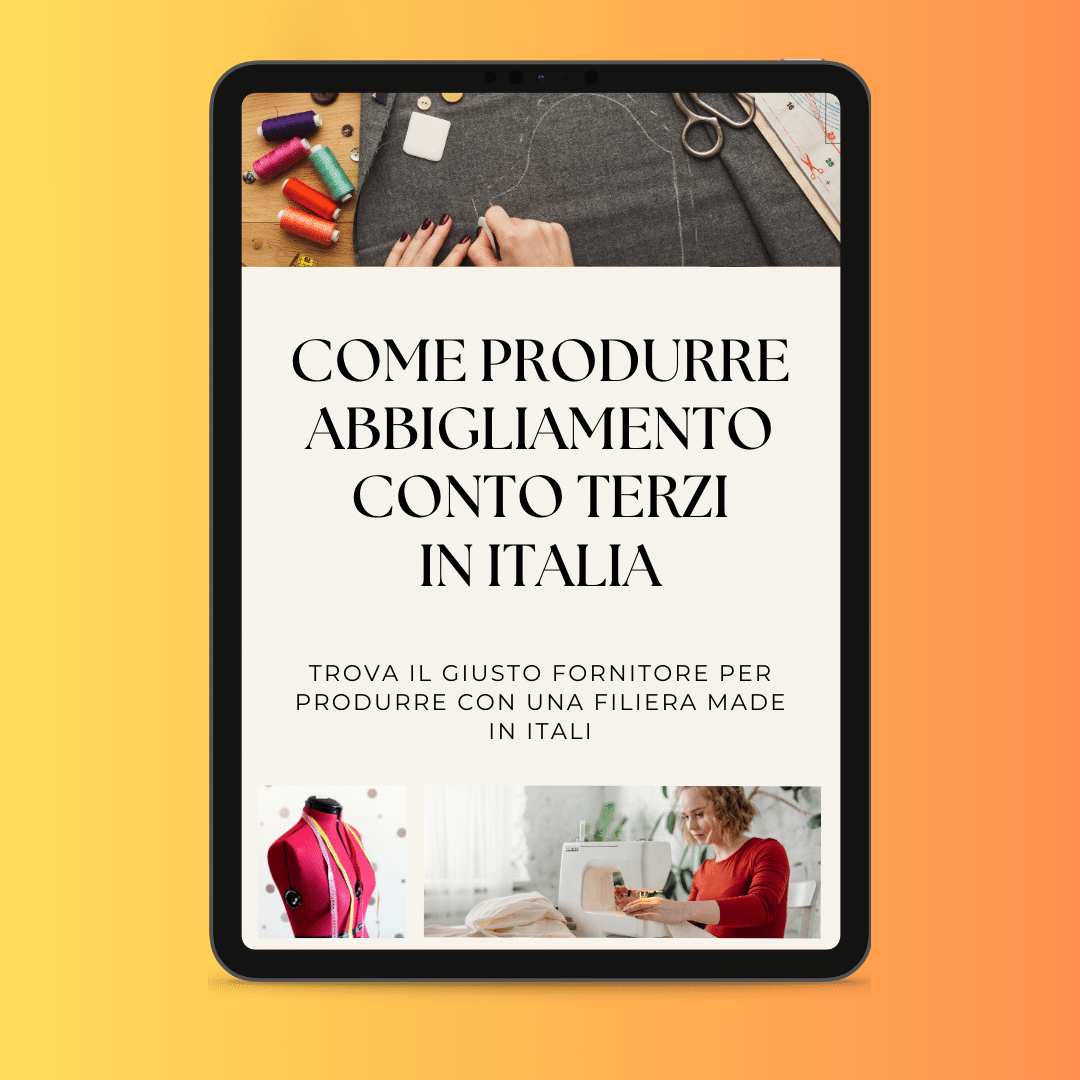

How to Manage Third-Party Apparel Production in Italy

Do you have an idea for a collection but don't know where to start to produce it? La contract clothing production in Italy is one of the most strategic solutions for turning a creative project into a concrete reality, even when starting from small quantities.

In this article, you will discover how to best manage every step of the production process: from contacting Italian suppliers to planning timing and costs, learning how to maintain consistency with your brand identity and positioning at all times.

We will analyse together the advantages and challenges of small volume contract clothing production in Italyan approach increasingly chosen by emerging designers and independent brands who want to ensure quality, sustainability and flexibility.

I am Corrado Manentiand I will guide you step by step along the way on how to make your collection unique, professional and market-ready.

What does it mean to produce contract clothing?

Before seeing how to manage contract clothing productionIt is important to understand what is meant by this term and how this production model works.

La contract clothing production consists in outsourcing the production of their garments to specialised workshops or companieswhile retaining full creative and strategic responsibility for the project. In practice, the brand or designer takes care of the concept, the designs and the choice of materials, while the production part, from cutting to tailoring and final finishing, is handled by external professionals.

It is a increasingly popular solution in the fashion worldbecause it allows you to turn an idea into a concrete collection without having to invest in your own machinery, personnel or facilities. Relying on the contract clothing production in Italy It also allows you to collaborate with qualified laboratories and experienced craftsmen, able to guarantee excellent quality and accurate control at every stage of the process.

In recent years, the contract clothing production in small quantities has become a benchmark for emerging designers and small brands. This approach makes it possible to sustainably manage costs and output pricestesting the market with limited runs of the highest quality. It is the ideal method for those who want to create handcrafted and flexible collections, without renouncing the strength of the Made in Italy.

The appeal of 'Made in Italy' products in the world:

La contract clothing production for small quantities is one of the most representative and valuable realities of the Italian fashion system. Within what we call The Production Chainthis model stands out for its ability to combine traditional craftsmanship and innovation, offering brands of all sizes the opportunity to create high-quality collections in Italy.

"Producing in Italy"has always been the highest aspiration of many international brands, particularly European and North American ones, who recognise the Made in Italy a brand of excellence, synonymous with care, precision and attention to detail. This applies as much to the established brandsas for the emerging designers who want to position themselves on a higher quality level and build a clear identity in the market.

The Made in Italy is not just a label, but a symbol of value and authenticity. Relying on the contract clothing production provides access to unique know-how while maintaining creative freedom and control over the end result. Thanks to the contract clothing production in small quantities, even small brands and start-ups can produce tailor-made quality garments, with the possibility of completely customising them according to their needs. This approach today represents one of the more flexible solutions to meet demands for customisation and uniqueness of the contemporary market.

However, it is crucial to understand one key principle: there is no such thing as a contract manufacturer to whom one can say 'I want to produce two of these and three of those'.

When working with the contract clothing productionyou, as a brand or designer, have to provide everything you need to start production:

-

- Artistic and Technical Designs in your collection

-

- Fabrics chosen in suitable quantities

-

- The accessories that make up the garment (zips, buttons, trimmings, rivets, etc.).

-

- Labels

-

- Paper Models

-

- A Prototype of each garment

For this if you do not have an established brand with a few collections on their shoulders the use of 'subcontractors' may not be the ideal situation to start with.

For this reason, if you do not yet have an established brand or a few collections behind you, collaborating with a subcontractor may not be the ideal way to start. Often, in fact, the contract clothing production is confused with formulas such as the Private Label or the White Labeltwo different models that meet different needs.

If you want to learn more about this, I recommend reading our Complete guide on Private Label and when to use itwhere we explain in detail the differences and where it can be an advantageous choice.

Although contract clothing production is not the easiest solution for those who are just starting out, you don't have to worry: there is also a method for those starting from scratch. In the course of this article I will show you our approach to managing the contract clothing production in Italyeven with small quantities, following a clear, sustainable and accessible path.

And if you are looking for reliable suppliers, we have created Easy Chain, a exclusive database which allows you to get in touch with producers, craftsmen and specialised workshops, built up over more than ten years of direct experience in the fashion industry.

The Be A Designer Method to arrive at the production of a fashion collection:

If this is the first article you read on our site, let me tell you about who we are and what we do.

In Be A Designer for over ten years we have been supporting designers, entrepreneurs and creative people who want to realise their own fashion collection in Italymaking possible what often seems complex or unattainable.

We do this thanks to a team of specialised professionals and a complete package "turnkey"which accompanies you every step of the way: from the building a differentiating brand idea, to the search for materialsup to the contract clothing production and the promoting your brand.

In this article we will take a closer look at how the world of contract manufacturing in Italyand I will explain in detail all the stages that precede the realisation of a collection: knowing them, you will be able to assess when, how much and how to produce your garments strategically and sustainably.

But first, it is important to make a big point: if you decided to produce your collection yourself, you would face several obstacles that may seem insurmountable.

1. BRAND IDEA:

Products are not born by chance. Even the most iconic garments take shape from asolid and recognisable brand ideaby a philosophy that combines values, aesthetics and personality.

It is what makes the difference between a simple piece of clothing and a product capable of moving and representing the wearer.

You might wonder: "Why is it so important?"

Because if your customers do not identify with your message, if they do not perceive your brand as aspirational, they simply will not buy.

Even when we talk about contract clothing production in small quantities, the brand idea always comes before the product. Only by clearly defining your identity will you be able to set a price consistent with the market and understand whether the production costs are sustainable.

In our approach the Brand Idea always comes first and only then the products of a collection.

Creativity must always respect the values of the brand and its customersotherwise they will not 'get it' and consequently NOT buy.

Corrado Manenti

2. PRODUCT IDEA:

The second major obstacle concerns theidea of products around which to build the collection. We have already seen how the answer to the age-old dilemma "does the brand or the product come first?" is clear: everything starts with the brand.

Many people entering the contract clothing production in Italy have a product in mind, but it often takes definition and development work to turn that idea into a drawing, a sketch or a technical illustration ready for production.

Making fashion small means learning its codes and know how to communicate with the people who will turn your vision into reality!

It is a teamworkIt requires different skills (stylists, pattern makers, tailors, technicians and consultants) that together create a coherent result, just like a band in which each musician contributes to the final harmony.

Even if you are already an experienced stylist, tailor or patternmaker, you may lack a complete vision to bring your collection to market in a winning way. Our method was created to bridge this gap and guide you step by step through to the production and launch of your brand.

THE BE A DESIGNER PORTFOLIO OF OUR LATEST PROJECTS FASHION

SUBSCRIBE TO THE NEWSLETTER AND DOWNLOAD FOR FREE:

Click on the button below

and follow the instructions:

MATERIAL RESEARCH: A challenge for small volume contract clothing production

La search for materials represents one of the most complex challenges in the contract clothing production in small quantities. Those entering the fashion world for the first time often do not yet have an established business structure or a VAT number, which can make it difficult to access the traditional supply channels. Industrial manufacturers work almost exclusively with structured companies and large quantities, making it complex for emerging designers to source fabrics and accessories in small quantities at competitive prices.

We of Be A Designer We have been working for years with leading Italian textile manufacturers and importers, building a strong network of relationships which allows us to obtain both a few metres of fabric for samples and orders of thousands of metres. Thanks to these partnerships, we are able to merge reduced orders several times a yearovercoming one of the biggest obstacles for those wishing to start production in Italy without large volumes.

If you do not have access to such providers, the options available at the beginning are often limited:

-

- Fabric shops by the metreThey supply materials at very high prices, often not reorderable, and only available for one-off items.

-

- Haberdashery or remnant shopsThey offer cheaper fabrics but with the same limitations, i.e. reduced quantities, impossibility of reordering and materials often derived from the processing of other brands. In many cases, these are offcuts or piece bottoms, with no certain information on provenance, manufacturer or technical characteristics, such as resistance to washing or other processing

However, these solutions have several limitations: the former offer quality materials, but at high costs and often cannot be reordered; the latter allow savings, but offer fabrics in small quantities, with uncertain provenance and technical characteristics that are not always guaranteed. In many cases, they are remnants or piece bottoms from other brands, without precise information on strength, composition or certifications.

For a contract clothing production in Italy of success, the search for materials must be planned very carefully. Working with reliable and certified suppliers is essential to ensure quality, availability and consistency over time. Only in this way will you be able to replicate the garments in your collection, maintaining the same aesthetic identity and quality that distinguishes your brand Made in Italy.

If you do not yet have access to structured suppliers or are taking your first steps in the industry, you can simplify your path thanks to the our consultancy servicepersonalised support designed to help you set up your fashion project, even if you are starting from scratch. We will guide you in choosing materials, defining your collection and preparing for the production phase, so that you can start your brand with a solid foundation and a clear vision.

How to sell your products?

If you thought the hardest part was producing your clothing line in Italyknow that the real challenge begins immediately afterwards: sell your products. Making a quality collection is only the first step, success depends on your ability to make it knownposition it correctly and get it in front of the right customers.

Each garment tells a story, has unique characteristics and appeals to a precise audience. It is no longer enough to wait for customers to discover your brand on their own: today you have to be the one to create connections, master marketing strategies and carefully choose the right distribution channels for your brand. Here are some basic questions:

-

- Where will you sell your products?

-

- Which distribution channels will you use to reach your market?

These are just some of the issues we will explore in this article, dedicated to the contract manufacturing of Made in Italy products. We will do this in the philosophy of Be A Designer, i.e. explain to designers and entrepreneurs how to create products that sell and are desired by our customers. Create a successful profitable business that allows you to live off your passions!

To make the most of these tips and get the best out of the our method you have two solutions:

1) ENROL IN OUR FASHION BUSINESS ACADEMY: The first online academy dedicated to the world of fashion and entrepreneurship, where you can independently learn the basics of creating your own project. Here you will find all the information you need to register for a special price

2) CREATE A COLLECTION WITH US: We will take your idea and turn it into something great, make your brand and products ready to be sold for you. You can book a free call with me and my team at any time by clicking HERE.

Whether you decide to learn how to make it yourself or you want to get your own made-in-Italy clothing collection, this article will try to reveal some secrets to success!

Are you ready? Let's get started!

The Process of Third-Party Apparel Production in Italy

Once you have defined your brand idea and chosen your materials, comes the most concrete phase of the journey: contract clothing production. This is where your design takes shape, going from drawing to finished garment. But how does this process actually work?

In the following paragraphs, we will look in detail at how small-quantity contract clothing production is structured, which professionals are involved in the different stages and because the Italian supply chainwith its specialisation, still represents one of the most efficient and popular models in the fashion world.

Understanding these dynamics will help you to planning your production strategicallyoptimising time, costs and resources, without ever losing consistency with your brand identity.

The operational phases of small-quantity garment production

La contract clothing production in small quantities is a complex and articulated process involving several professional figures and specialised skills, from the creation of the prototype to the final garment manufacture. In the Italian fashion industry, it is rare to find a single company that manages all phases in-house: the strength of our supply chain lies precisely in the specialisation. Each company focuses on a specific area, guaranteeing results of the highest technical and craftsmanship level.

Here are some of the main figures involved in production:

-

- ModellersThey only deal with the creation of the paper pattern of a garment.

-

- PackersThey assemble the garments, but to do so they need all the materials, including labels and accessories, to be supplied by the brand.

-

- CuttersMany companies concentrate solely on cutting the fabric, supplying the parts ready for packaging.

-

- PrintworksThey print the fabric, but the suitable fabric must be identified and supplied by the customer.

-

- PrototypistsThey only make prototypes before actual production.

This fragmentation of the supply chain makes a close collaboration between the brand and the different production realitiesin order to achieve an end result that respects both the quality standards and the creative vision of the brand.

For this reason, Be A Designer is proposed as single point of contact capable of coordinating every stage of the contract clothing production in small quantitiesfrom the conception phase to the realisation of the finished garment. Thanks to our method, we help designers and brands to optimising time and resourcesmaintaining constant quality control and ensuring clear and professional management of the entire production.

Do you want to start your own contract clothing production in Italy with the support of professionals? Contact the Be A Designer team and find out how we can accompany you step by step in the realisation of your Made in Italy collection.

The advantages of toll manufacturing

Choose the contract clothing production in small quantities offers numerous advantages, especially for brands and companies wishing to focus on their core business and optimise resources, time and costs. This production model allows the most technical steps to be delegated to experienced professionals, while retaining full creative control over the final result.

Among the main benefits are:

- Cost reduction: Outsourcing production avoids the high investment needed to run an in-house plant, reducing fixed expenses and optimising the budget.

- Greater flexibility: thanks to the contract clothing production in small quantitiesyou can quickly adapt to market fluctuations and new trends by testing designs or capsule collection without having to bear great economic risks.

- Access to specialised expertise: collaborate with professionals from Italian supply chain makes it possible to exploit a unique know-how of craftsmanship, quality and innovation. The sharing of experience and resources guarantees excellent results and high production standards.

A further advantage of the contract manufacturing in Italy is the possibility of diversifying the offer. By delegating part of the production, a brand can introduce new lines, explore different markets or develop experimental collections while maintaining high levels of quality.

For brands already active in the fashion industry, the model of the contract clothing production in small quantities is an ideal strategy to test new collections, experiment with innovative materials or launch exclusive products without committing excessive resources. It is a smart way to grow sustainably while remaining agile and competitive in an ever-changing market.

Producing clothing in smaller quantities allows us to test new designs, reduce waste and offer greater exclusivity to customers, helping us to create an emotional bond with the brand.

Do you want to find out how to make the most of the advantages of contract manufacturing to grow your brand? Contact us now! We will help you build a tailor-made production strategy for your fashion project.

What can you produce with contract manufacturing?

La contract clothing production in small quantities offers extraordinary creative freedom, allowing a wide range of garments to be made, from the most structured tailored models to the ready-to-wear collections. One can develop jackets, trousers, skirts, shirts, dresses or outerwear, as well as casual and streetwear lines, all sharing a high level of customisation and typically Italian craftsmanship.

This production model is ideal for those who wish to offer unique and differentiated collectionsbuilt around a well-defined brand identity. It allows you to experiment with shapes, materials and details, creating capsule collections or niche mini-lines that fully reflect your own stylistic vision.

A further advantage of the contract clothing production in Italy is the possibility of maintaining the same quality even on small runs: thanks to the flexibility of the craft workshops and the precision of the production techniques, it is possible to obtain garments with attention to detail without having to deal with the costs of in-house production or large industrial volumes.

In this way, emerging designers, start-ups and independent brands can develop exclusive and valuable collections, testing the market and refining their positioning in the fashion industry.

Garment production: differences between tailoring and mass production

In the fashion world, understanding the difference between sartorial production e mass production is essential to choose the most suitable model for your brand. Both approaches offer specific advantages, but respond to very different needs and market strategies.

The characteristics of tailoring production

La sartorial production is characterised by its craftsmanship and attention to detail at every stage of the process. Each garment is made with care, often made-to-measure or in limited editions, to guarantee a high level of customisation and quality. It is the ideal choice for brands that want to focus on uniqueness, precision finishing and authenticity of the Made in Italy.

The advantages of mass production

La mass productionInstead, it emphasises quantity and speed. This approach makes it possible to reduce unit costs through economies of scale and to respond quickly to market demand. It is the most suitable solution for companies wishing reach a wider audiencewhile maintaining a good balance between quality and price competitiveness.

Which companies should opt for tailor-made production?

La sartorial production is perfect for brands wishing to position themselves in the luxury and high fashion segment, where exclusivity, craftsmanship and attention to detail are essential values. In Italy, the home of manufacturing excellence, there are numerous artisan workshops specialising in limited productions, capable of transforming each garment into a unique work.

Naturally, this choice entails higher costs than mass production: craftsmanship requires time, expertise and high-quality materials, elements that affect the final price of the product. On average, tailor-made garments can start from approx. € 600 per unitdepending on the complexity of the design, machining and hand finishing required.

Choose the sartorial production in Italy means not only standing out in the market, but also enhancing and preserving Italian craftsmanship and design, internationally recognised for quality and style. It is the ideal solution for brands wishing to offer collections of handmade luxurydesigned for exclusive boutiques or haute couture ateliers.

Do you want to understand which type of production is best suited to your brand? Contact the Be A Designer team to receive a personalised consultation and find out how to structure your collection according to your brand positioning.

Costs and quality in small-quantity apparel production

When we talk about contract clothing production for small quantitieswe generally refer to the production of 50-100 pieces per model. This type of production tends to be more expensive on a per-unit basis than mass production, but offers numerous advantages in terms of flexibility, exclusivity and speed in responding to market trends.

What does it mean to produce in small quantities?

-

- A model refers to a specific design or style of a garment.

-

- A variant of a model represents differences in colour, fabric or other features, while keeping the basic design unchanged.

Practical example:

If we produce 50 pieces of a pattern in five standard sizes, 10 pieces per size will be produced. If the model has two variants, such as two different colours, production is further divided: 5 pieces per size for each variant. Similarly, with a production of 100 pieces per model and two variants, we will obtain 10 pieces for each size and variant.

This small-scale production system allows greater customisation and adaptation to specific market or customer tastes, while keeping stock levels under control and reducing the risk of unsold stock.

How to ensure quality in limited production

To ensure quality in limited production, it is essential to establish strict quality control standards, select reliable suppliers and follow all stages of the production process with attention to detail, especially since we produce small quantities and cannot afford it!

La quality of clothing is a key element in production processes, influencing the brand image and customer satisfaction. Ensuring high standards means carefully selecting materials, carefully controlling workmanship and providing durable, quality garments.

Creating a unique and distinctive design is essential for market differentiation and attracting consumers. Enhancing the aesthetics, originality and comfort of garments is a key element in winning the trust of customers and retaining their loyalty over time.

Implementing strategies aimed at ensuring high standards in production, such as strict quality controls and collaborations with industry experts, allows companies to maintain a constant level of excellence and be recognised for the quality of their products.

Do you want to start your own contract clothing production in Italy with a partner who will follow you every step of the way? Request a personalised consultation with the Be A Designer team and find out how we can help you structure your collection, choose the right suppliers and manage every production detail professionally and strategically.

What kind of services does your clothing manufacturing company offer?

Our company offers contract clothing production services for small quantities, creating high quality garments made in Italy.

How can I contact your company for information on clothing production?

You can contact us via the contact form on our website or by calling our offices directly to receive all the necessary information about our contract clothing production.

What kind of garments do you produce with the sub-contracting service?

We produce a line of high fashion clothing, including jackets, down jackets and garments, guaranteeing the highest quality and made in Italy production.

What is special about your contract clothing production for small quantities?

Our contract production for small quantities is characterised by the attention to detail, the wearability of the garments and the sartorial quality we offer to companies in the sector.

Do you also collaborate with clothing shops for the production of made-to-measure garments?

Yes, we offer customised clothing production services for clothing shops, providing a wide range of options and a personalised service.

Do you supply samples for contract clothing production for many companies?

Yes, we have sample collections for the production of contract clothing for many companies, offering a choice of different options and styles.

What are the main characteristics of your Italian-made garments?

Our made-in-Italy garments are characterised by the quality of the materials used, tailor-made design and attention to detail, offering a high quality and prestigious product.

The article offers an immersion into the world of Italian fashion, where contract manufacturing for small quantities is crucial to maintain high standards of quality and customisation. The 'Made in Italy' formula is not just a brand name, but a guarantee of craftsmanship excellence. This approach not only respects tradition but also supports innovation, enabling small designers to create unique collections. The ability to adapt to the needs of a market that prizes uniqueness is reflected in every detail, similar to the quest for exclusivity that we might find in a distinctive accessory such as a silver handbag. Be A Designer's production highlights the importance of careful and customised work, underlining how authenticity and passion for detail are essential values in the Italian fashion industry.